Categories

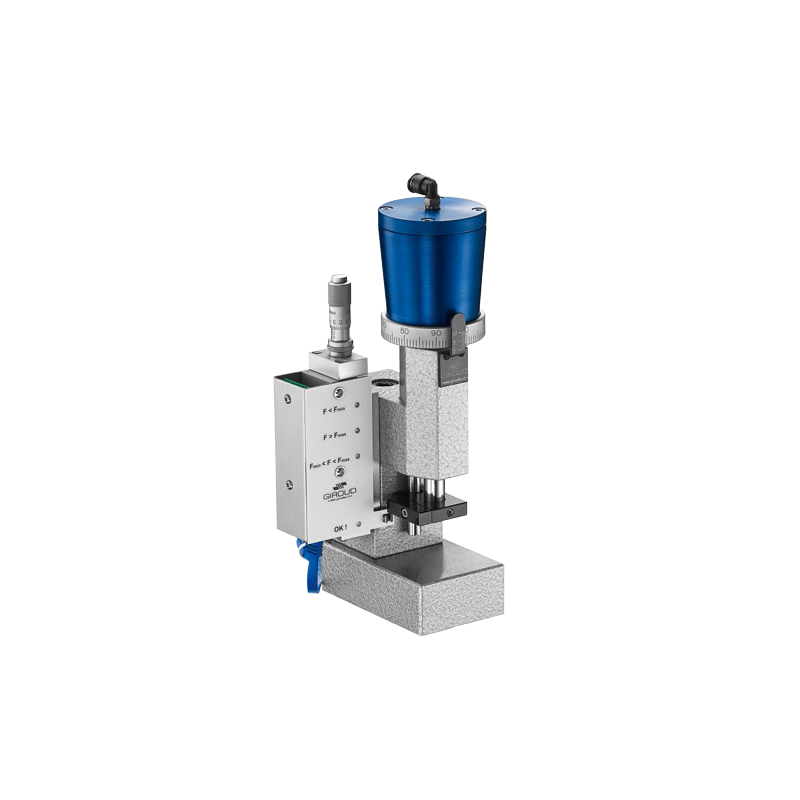

Pneumatic Insertion Press

Highly multidisciplinary. Can be used for many applications: insertion, crimping, marking, etc...

Pneumatic Insertion Press

Features

Advantages

• Highly multidisciplinary. Can be used for many applications: insertion, crimping, marking, etc...

• Increase productivity and reduce fatigue.

• Down without slip-stick ensuring a smooth and precise operation and a minimum risk of deformation of the workpiece.

Features

• Insertion force between 0 and 600 N for the types S50.x, and between 0 and 1500 N for the type S100.

• 20mm standard stroke for type S50.x and 40mm for type S100, with an adjustment to 1/100th.

• Exactly reproduces the movement of a manual watchmaker press : down the spindle without force on the workpiece, then applying pressure.

Pneumatic Insertion Press

Options

Two hands safety control system

Two hands safety control system

LED lighting

LED lighting

Option FC

Option FC

Spindle locator

Spindle locator

Control module

Control module

Overview

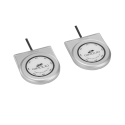

Our precision tables

Manufacture

These tables are almost exclusively made of greyrncast iron (GG25) and all the surfaces are ground. An anodized aluminium version with inox screws can be obtained on demand. They are fitted with vernier scale, graduated to 1/100th of mm, and can be reseted to zero.

Load capacity

These tables can support heavy loads despite their small size. We advise to install integrated lubricationrnsystem on tables which must translate heavyrnloads (see page 21).

Maintenance

The simplicity and robustness of those tables require minimum maintenance. An occasional cleaning and a regular lubrication is enough to keep these tables in perfect condition.

Operating environment

Thanks to their robustness, these tables can operate in the toughest environments. We recommend the installation of protections (see page 21) when these tables are used in particularly dirty environments (dust, abrasive, metal chips, etc..)

Options

Short vernier scale, handwheel, roller counter,rnangle drive, locking mechanism, pairing, differentrnmachining, integrated lubrication, protection systems,rnsurface coating (nickel plating, phosphaterncoating, etc…)

Sub-contract work

Most of our tables are delivered without fixing holes. This is why we will willingly provide all the sub-contracting work (machining, surface treatment, assembly of the equipment) on our tables, as well as any associated parts. So please do not hesitate to contact us for more informations.

More details

For more details download our catalog